Central Control Technology

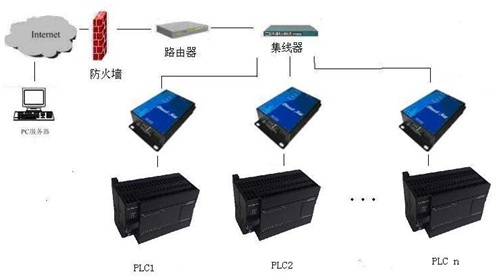

The central control unit connects to sub-units via communication protocols such as TCP/IP and I/O, enabling unified management of CNC machining centers, intelligent measurement centers, industrial robots, and industrial AGV rail systems to coordinate and ensure smooth, orderly operation.

Through programming, the central control unit easily supports adding or removing sub-units and adjusting production cycles to adapt to changing demands.

Using EMRP management software, it maintains consistent part coordinate systems across machining, measurement, and material handling processes, enhancing manufacturing accuracy. Quality analysis software monitors tool wear in real time and provides immediate feedback to the machining units, enabling intelligent production oversight.

Sensor Technology

The system integrates vision sensors, laser sensors, and probe sensors to enable key functions including workpiece identification, automatic program calling for machining/measurement, material handling/sorting, and safety protection.

CNC Technology

The company utilizes advanced precision guide technologies—such as air-bearing guides, linear guides, and shaft systems—alongside transmission methods including linear motors, direct-drive motors, ball screws, and gear racks. Combined with mature CNC technology, it offers multi-axis full closed-loop servo control units in various configurations (single or multi-axis, linear or rotary) to deliver tailored, professional smart machining and measurement solutions.

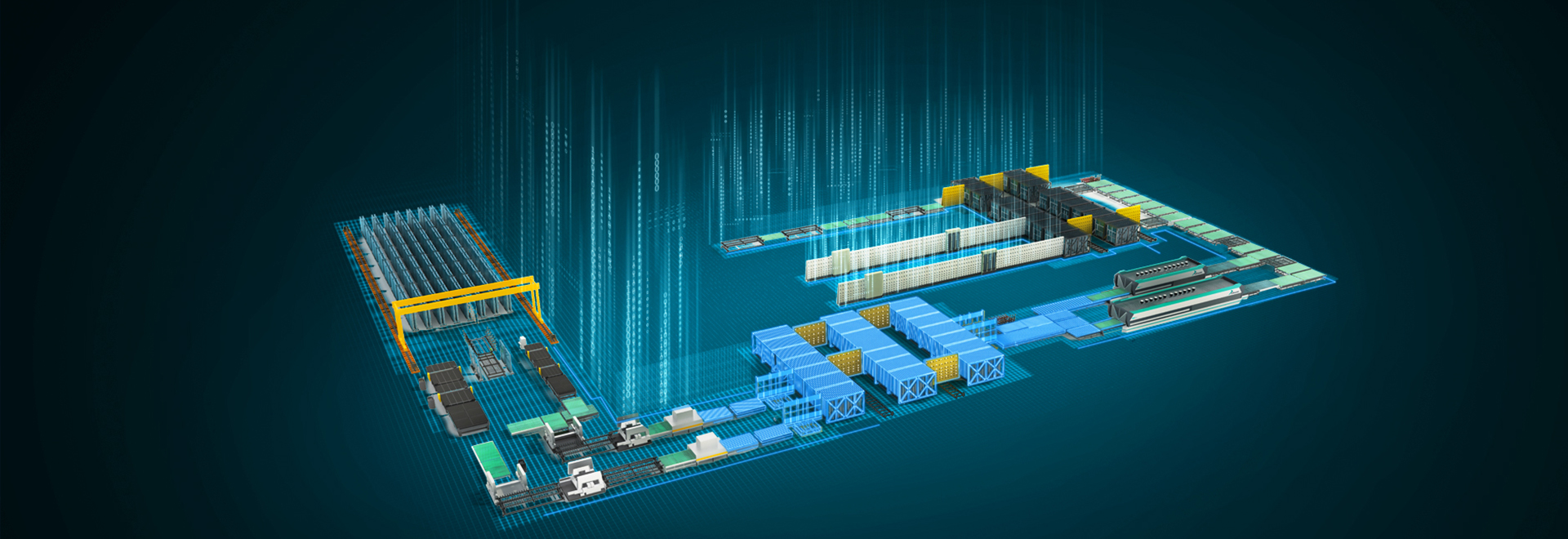

EMRP Management Software

EMRP (Enterprise Manufacturing & Quality Management System) is a quality-focused platform that collects and analyzes data across the entire product lifecycle—from R&D, manufacturing, and sales to customer feedback. It enables real-time management and process control for quality-critical nodes such as design, machining, metrology, and personnel, empowering intelligent quality control in smart manufacturing.

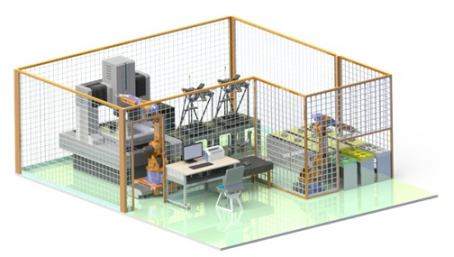

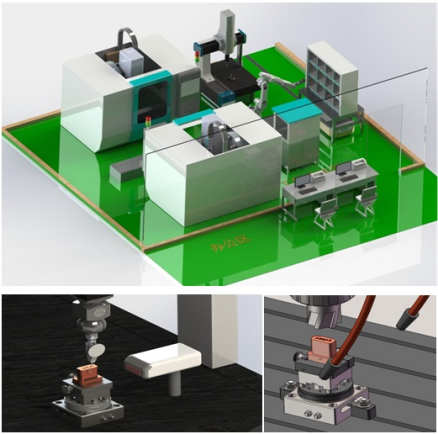

Example:

· Electrode Smart Manufacturing Cell: A fully automated unmanned workshop

· 3D coordinate measuring machine

· Two CNC machining centers

· One industrial robot

· Alignment device

· Cleaning machine

· Storage racks

· Precision fixtures

XX Part Intelligent Inspection System:

· Composite measuring machine

· Two comparators

· One industrial robot

· Automatic feeding system