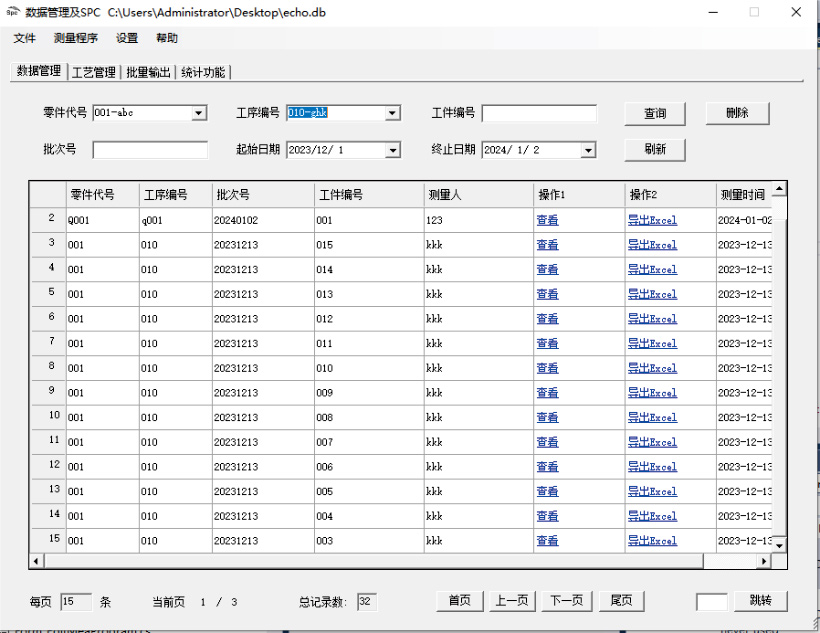

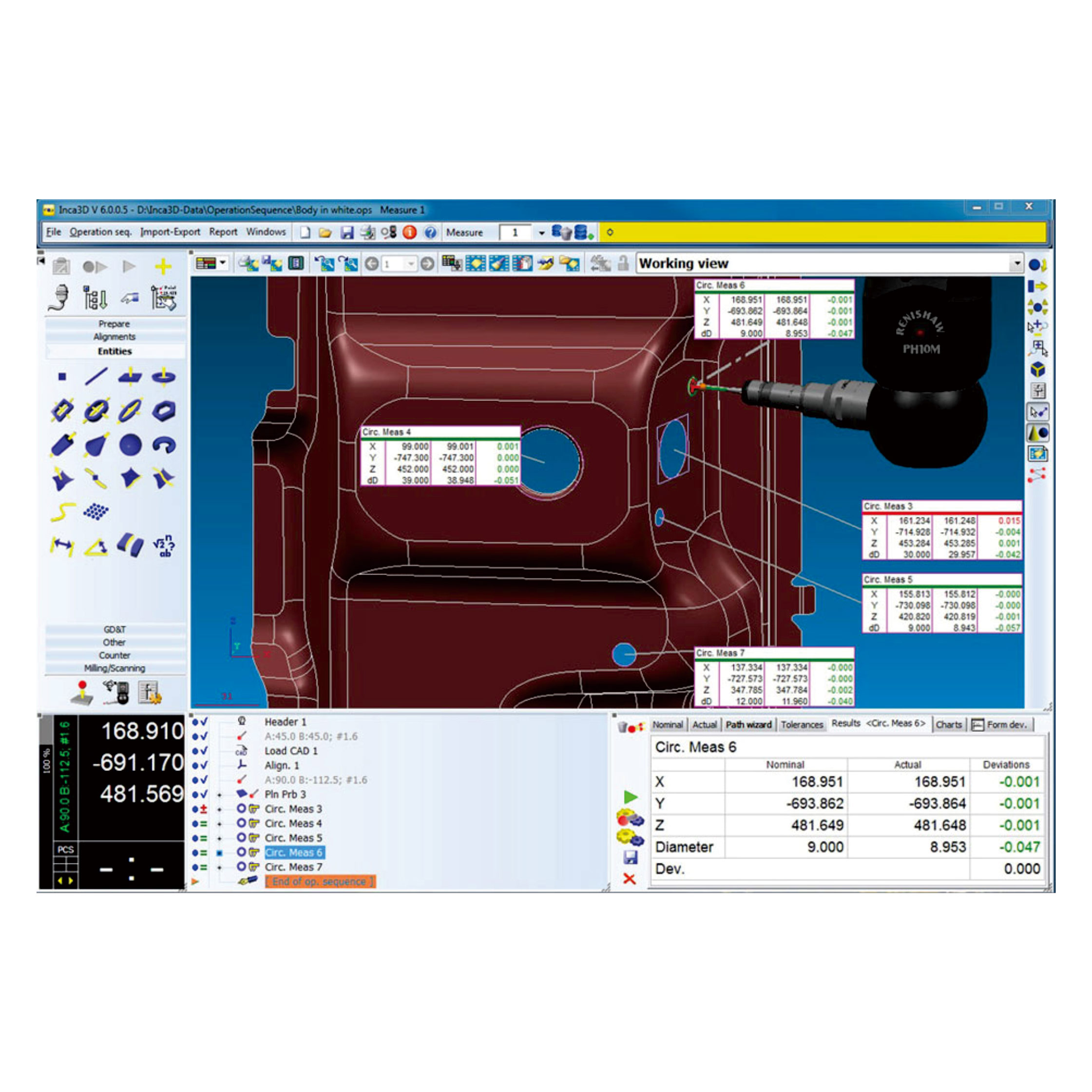

INCA3D is an ideal measurement application software for industries such as mold and die manufacturing, tooling, sheet metal, free-form surfaces, aerospace, and automotive manufacturing. It can also be customized to meet client needs in other fields.

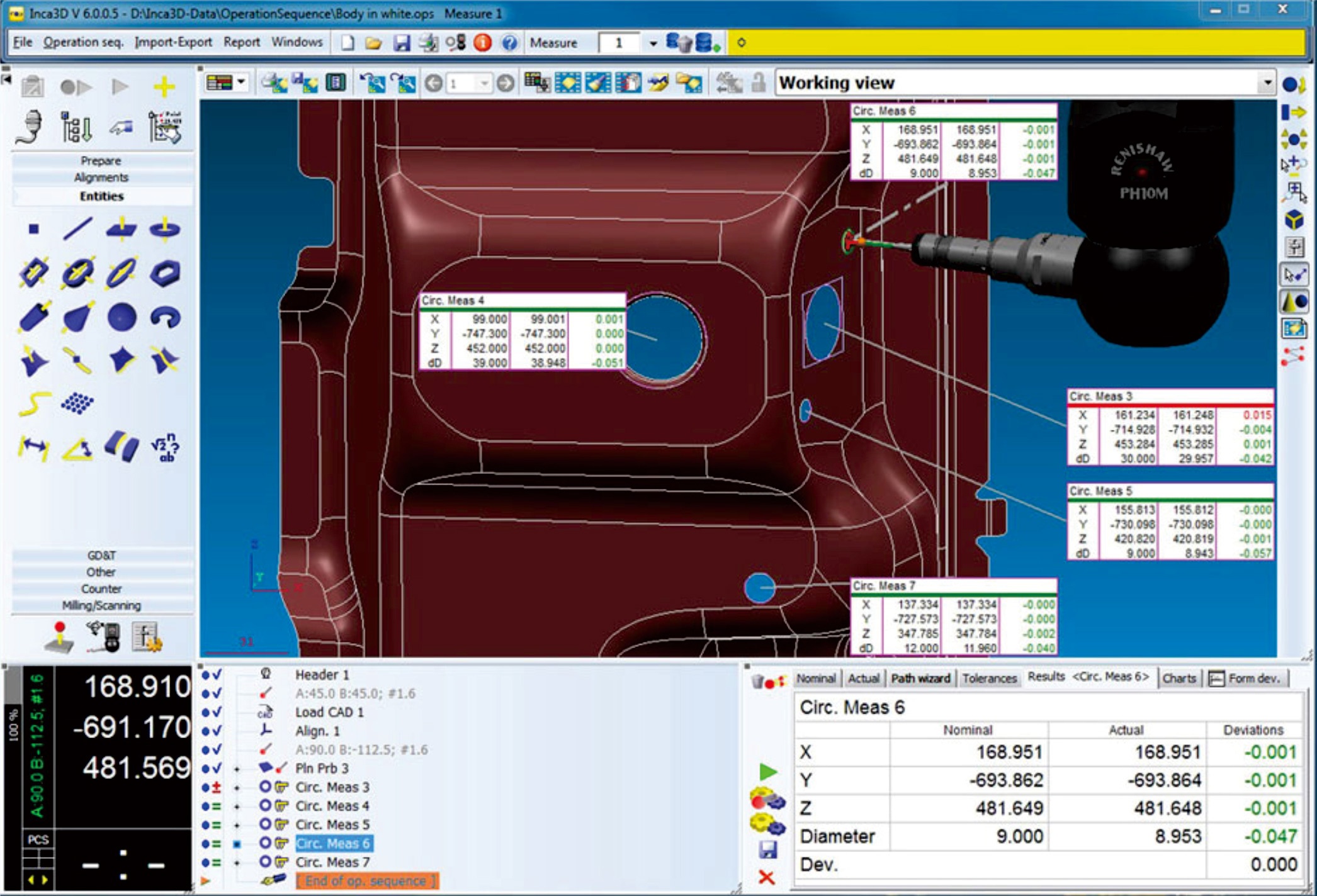

By leveraging a multi-arm CMM (Coordinate Measuring Machine) networking mode, INCA3D addresses challenges in white body measurement, establishing itself as the "intelligent hub" in automotive R&D. This innovation has solidified its position as a leading brand in multi-arm CMM software and paved the way for the development of a nationally recognized five-axis measurement software. Its breakthroughs in precision enhancement represent a groundbreaking technological advancement in the industry.

Multi-CMM Networking Mode: Enables interconnected operation of multiple measuring machines.

Turntable Axis Support: Compatible with additional rotary table axes.

21-Error Correction: Comprehensive error compensation for enhanced precision.

Temperature Compensation: Automatic adjustments for equipment and workpiece thermal effects.

Real-Time Dual/Triple Management via TCP/IP: Features auto-synchronization and crash prediction for robust system control.

Extended Software Options: Multiple output formats, sheet metal measurement, advanced extensions, macro commands, and tubing inspection.

Third-Party Device Compatibility: Most equipment from other manufacturers can be retrofitted for use with INCA3D software.