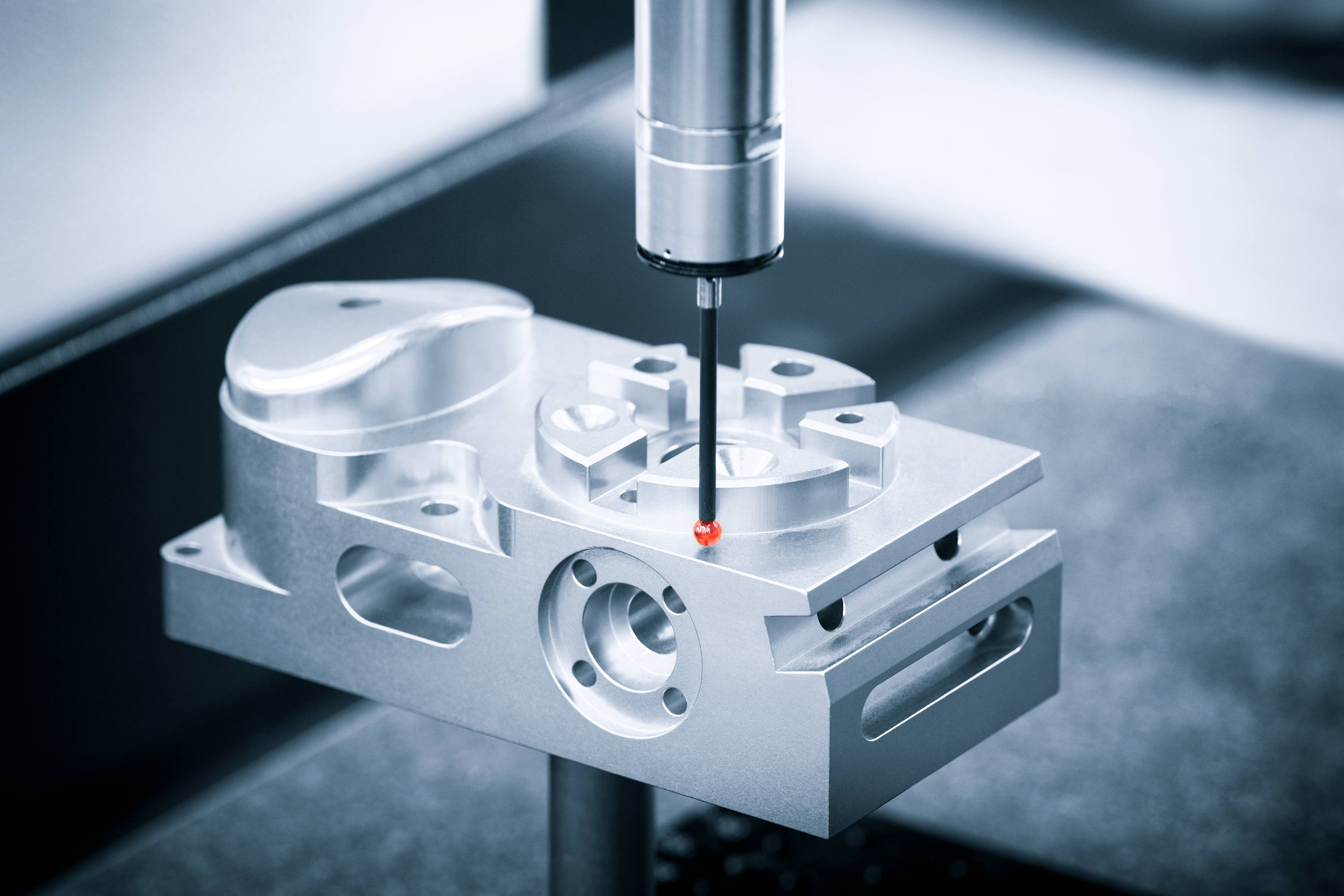

Complex Geometry, Tight Tolerances

Mold cavities feature complex free-form surfaces and intricate details (edges, fillets). Tolerances often within ±5μm. Conventional measurement easily misses fine features.

Unquantified Wear & Rework

Mold wear during production and post-rework surface changes are difficult to quantify. Reliance on technician experience compromises quality consistency.

Costly & Lengthy Trial Runs

Assembled molds require repeated on-site trials. Long adjustment cycles when issues arise directly increase new product development costs and time.