Mastering Full-Stack Independent Core Technology

Defining China's benchmark for precision measurement with full-stack independent technology

3 global R&D centers + university partnerships, team with 60%+ master's degrees, 120+ patents breaking foreign monopoly; dual ISO quality control, equipment tested 48 hours + 200+ calibrations; embodied intelligence and other technologies improve efficiency by 50%-90%, EMRP reduces downtime by 40%; providing full-chain solutions and intelligent inspection units, empowering high-end manufacturing to reduce costs and increase efficiency.

AEH builds a three-dimensional R&D system with 'global vision, Chinese innovation', led by Dr. Song Jianzhong with an international team where master's and doctoral degrees exceed 60%. Relying on three R&D centers in Xi'an, Germany, and France, and partnering with Xi'an Jiaotong University and other institutions, we form an innovation loop of 'basic research - application development - product transformation'. The company has accumulated 120+ patents and software copyrights, with invention patents exceeding 40%. Our core NET·DMIS software is China's first measurement platform certified by Germany's PTB, featuring a heterogeneous DMIS conversion engine that seamlessly parses mainstream 3D formats and MBD annotations, breaking foreign monopoly. The company has participated in formulating 4 national standards and reached international advanced levels in multiple key technical indicators.

AEH has established a quality management system covering the entire product lifecycle, strictly implementing ISO9001 and ISO/IEC17025 standards, and adopting DFMEA methods to eliminate risks at the design stage. Through self-developed core motion components and vertical integration, we ensure precise control from materials to assembly. The production process has 28 quality control points, each device undergoes 48-hour continuous stability testing, and completes 200+ precision calibrations in a constant temperature workshop at 20±1°C. Combined with a full-process quality traceability system, we ensure ultra-high reliability and consistency of products.

AEH's embodied intelligence technology achieves a measurement paradigm revolution by endowing equipment with spatial perception and adaptive capabilities, supporting arbitrary workpiece placement without fixtures, and intelligently identifying matching programs. Combined with five-axis probes and vector normal sampling technology, it achieves precise measurement of complex curved surfaces. This technology can reduce measurement time by 70%-90%, supports intelligent programming and real-time large point cloud parsing, data directly connects to MES/ERP and automatically generates SPC analysis, advancing quality control from 'post-analysis' to 'process perception' stage.

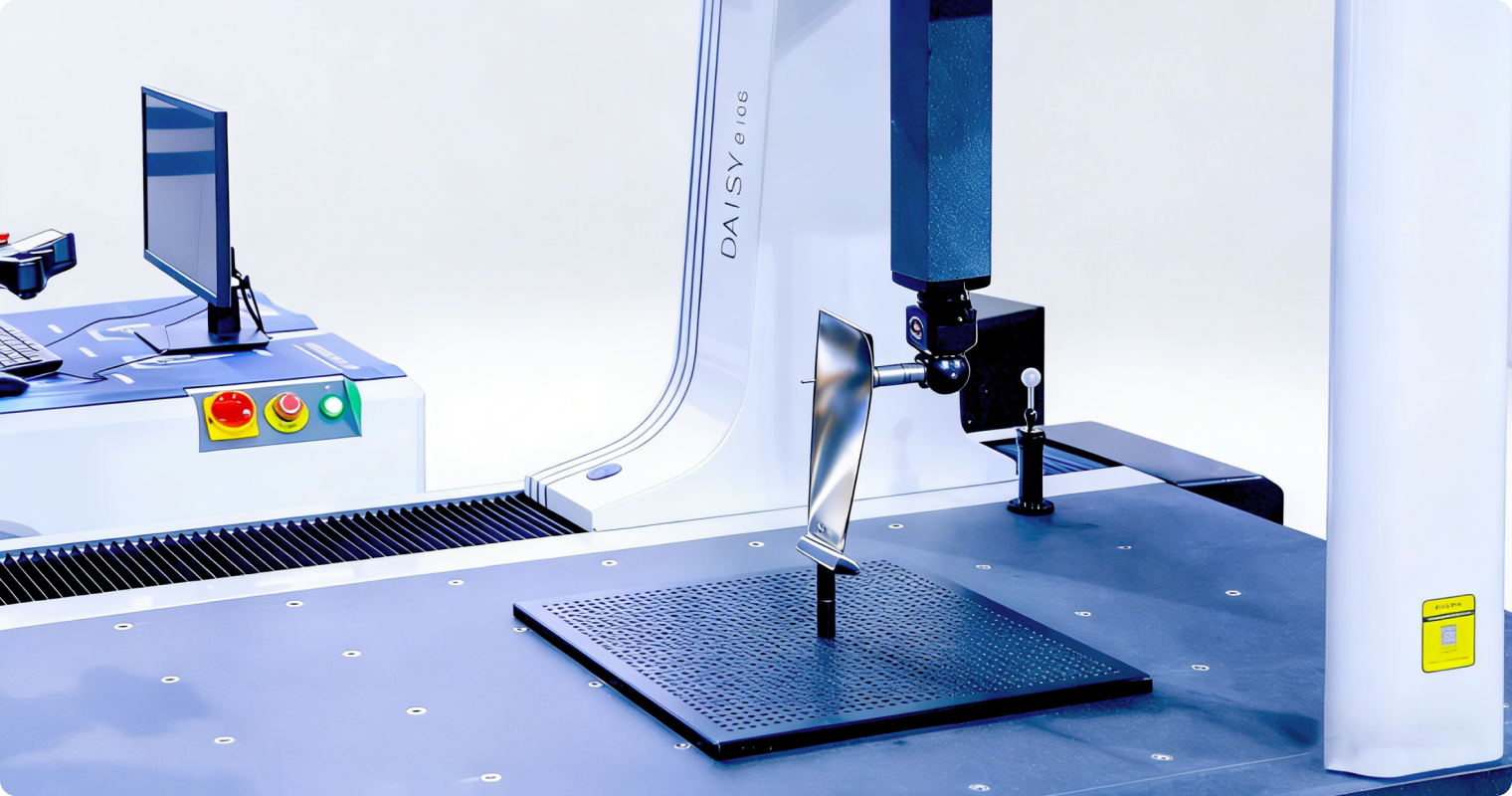

For complex curved surface parts such as aero-engine blades, AEH provides complete precision inspection solutions. The system is equipped with various scanning probes, supporting contact and non-contact measurement. Dedicated software features multiple fitting and tolerance evaluation algorithms, compatible with multi-source data. Innovative optical rapid multi-axis measurement systems and unique dual-laser four-axis measuring instruments, combined with four-axis motion and vertical clamping, effectively overcome workpiece deformation. This technology has been applied to enterprises such as Xi'an Aero-Engine and AECC South, improving inspection efficiency by 50% while maintaining micron-level precision.

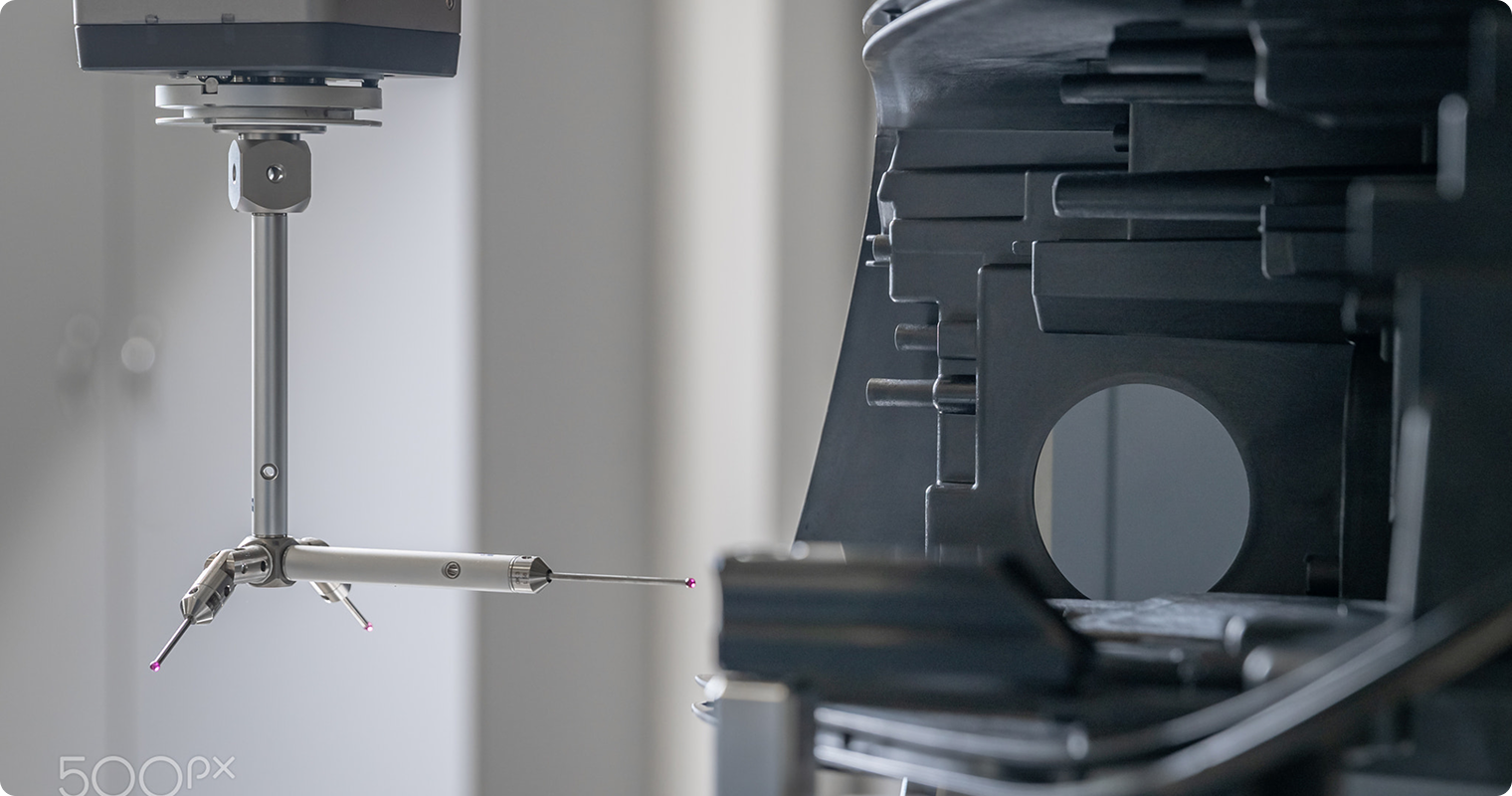

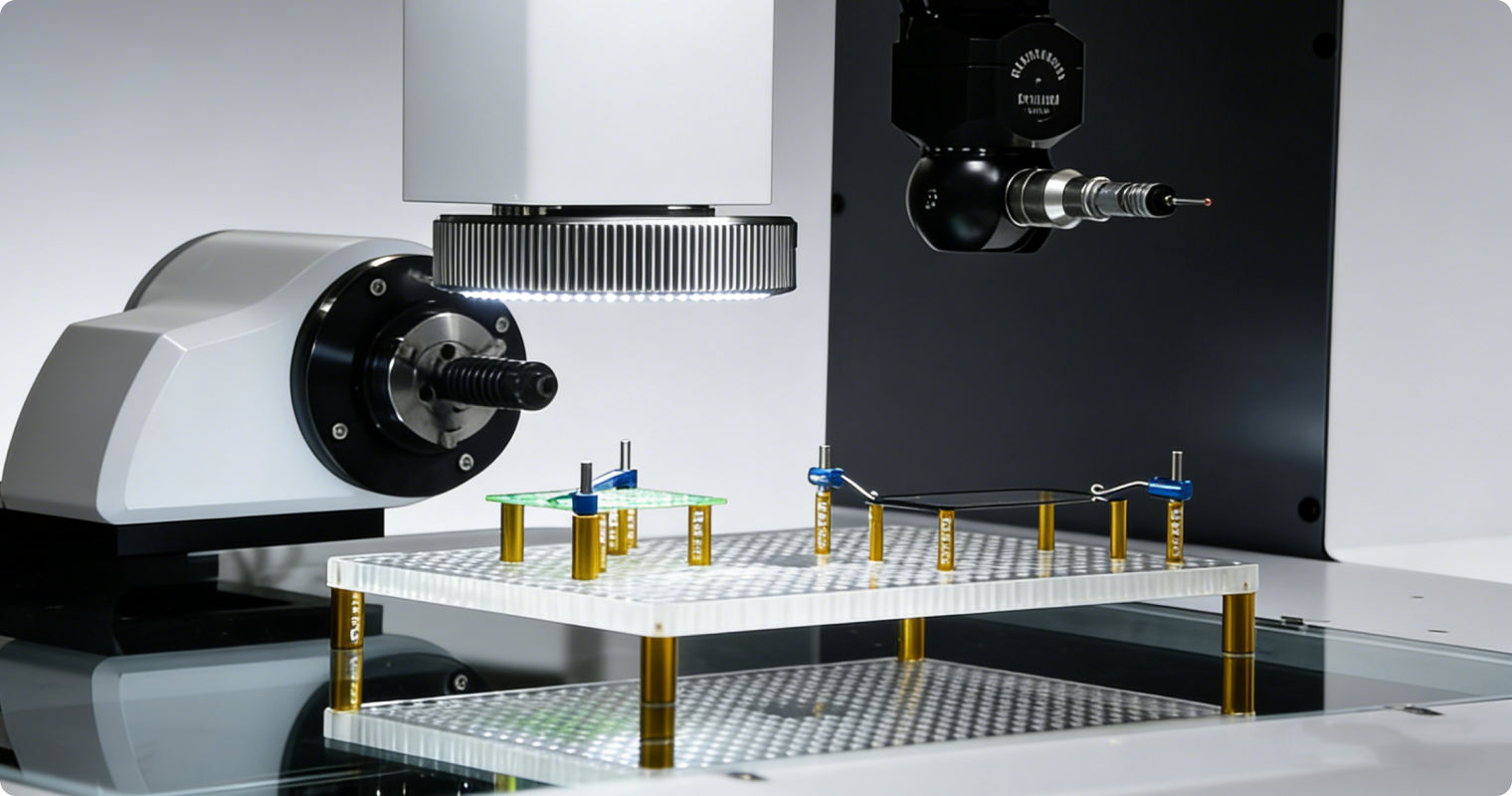

AEH's composite measurement technology integrates contact probes, optical scanning, and laser sensors on the same platform, intelligently switching detection methods based on a unified coordinate system, achieving full-element measurement of complex workpieces in one setup. Through multi-sensor data fusion algorithms, it solves the cumulative error problem of multiple positioning, improving measurement data consistency to over 99.5% and detection efficiency by 40%, widely applied in aerospace, precision electronics, molds and other fields.

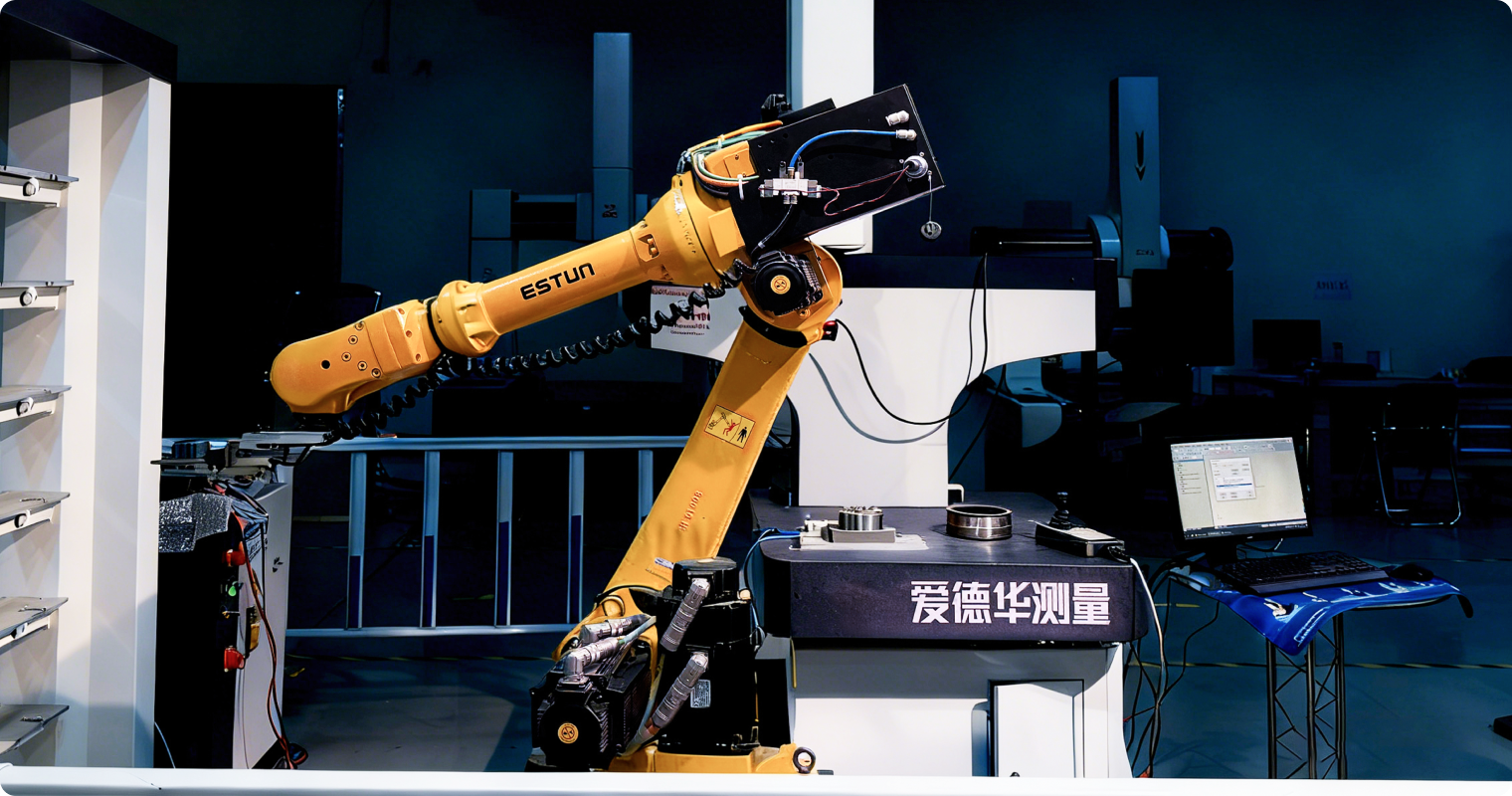

AEH builds flexible intelligent inspection systems by integrating industrial robots, conveyor lines, and multi-sensors. The unit adopts modular design, with independent PLC as the core for precise coordinated control, equipped with RFID system to automatically identify workpieces, call programs, and complete data judgment and traceability. Robot loading/unloading combined with high-precision positioning, full-process equipped with safety protection, ensures 24-hour unmanned safe operation, significantly improving production line inspection efficiency and intelligence level.

Relying on full-industry-chain R&D capabilities, AEH builds a complete product matrix covering CMM, optical imaging, gear, and cantilever measurement, providing one-stop solutions from hardware to software. The company achieves full-chain independent technology layout from structural design, electrical control to core algorithms. Based on over 20 years of technical accumulation and data from nearly 10,000 customers, integrating dynamic error compensation and temperature adaptive technology, and through industrial IoT and cloud computing architecture for real-time intelligent data analysis. Through the EMRP system, it achieves unified management of multi-source data, automatic generation of inspection processes, and seamless integration with enterprise PLM/MES/ERP, forming a closed-loop quality management system of 'measurement - analysis - decision - optimization'.

EMRP is AEH's self-developed next-generation quality management hub, based on full-element digitization of 'people, machines, materials, methods, environment, and measurement', integrating heterogeneous DMIS conversion engines to break data barriers between multi-brand equipment. The platform collects inspection data in real-time, monitors equipment and environment, combines RFID for full-process material traceability, uses intelligent algorithms for trend warning and root cause analysis, promoting quality control from post-processing to pre-prevention. Practice shows that EMRP can help customers reduce production line abnormal downtime by 40% and shorten supplier problem handling cycles to 5 days.